sheet metal drawing standards

ANSI Y1471-1971 Gear Drawing Standards Part 1. Standard Sheets are available both in the US Customary units accessible below and in Metric units.

January 1 2020 - GMNA.

. In the construction industry all drawings are carried out to a british standard referred to as bs 1192. Sheet metal shops can bend to tolerances of 015 or 04mm. Sheet metal parts are known for their durability.

The minimum recommended sheet metal flange bend length avoid cracks in the bending area. Enter 5mm in the Default Bend Radius field. 94 The drawing scale for system layout drawings should be coordinated with.

Defining the Sheet Metal Parameters This task shows you how to configure the sheet metal parameters. Ad Easy Tool Modification Shorter Lead Times And Lower Tooling Cost With Quintus. D 25T R see below The height can be less but it required secondary operations and is far more costly.

Most-Recent Revision Only 260 Not False 0 Publisher. If you have any questions after reading through this guide. 2 blade mechanical broadheads.

9981870 - Drawing Compounds Water Based for Sheet Metal. Gauge is another unit for measuring sheet metal thickness. Details for circular and elliptical corrugated metal controlled low strength material clsm installation 209-02 209-01 linear measures eb 09-036 090210 check dams sheet 2 of 2 209-03.

I am not aware of standards for them separate from any other kind of fabrication drawing. I do lots of sheet metal drawings. I have never checked the accuracy of the punching or laser cutting or whatever.

The Standards Committee that approved the code or standard was balanced to assure that individuals from competent and concerned interests have had an opportunity to participate. Click the Sheet Metal Parameters icon. Since sheet metal cannot be bent to a 90-degree position without breaking at sharp corners all bends will have an acceptable bend radius.

3 blade mechanical broadheads. Heavy rock riprap and fill detail Typical cross-section looking downstream. Drawing Submittal Status and Design Notes.

It reviews general dimension standards as well as requirements for. There are other measurement units used to categorise metals by thickness though. ASTM 11 SMACNA 9 MPIF 11 ICBO 1.

Our deeper draw capacity offers you completely customized options. Upper-left corner of the drawing sheet touching the top and left border lines 2. Narrow Your Results Revision.

92 The recommended reduced scale for fixture designs are 12 15 110 120 and 150. Lower-left corner of the drawing sheet touching the left and bottom border lines 3. Local depression and pressure line.

Your tolerances to and from bends should reflect this. Most-Recent Revision Only Clear all. The Sheet Metal Parameters dialog box is displayed.

Heavy rock riprap and fill detail Typical cross-section looking downstreamdwgpdf. SCS articulates the CAD standards that will enable SMACNA members and the rest of the AEC community to apply CAD effectively to mechanical fire protection and plumbing design and construction. Minimum Sheet Metal Flange Bend Length 3 x Sheet Thickness Bend Radius.

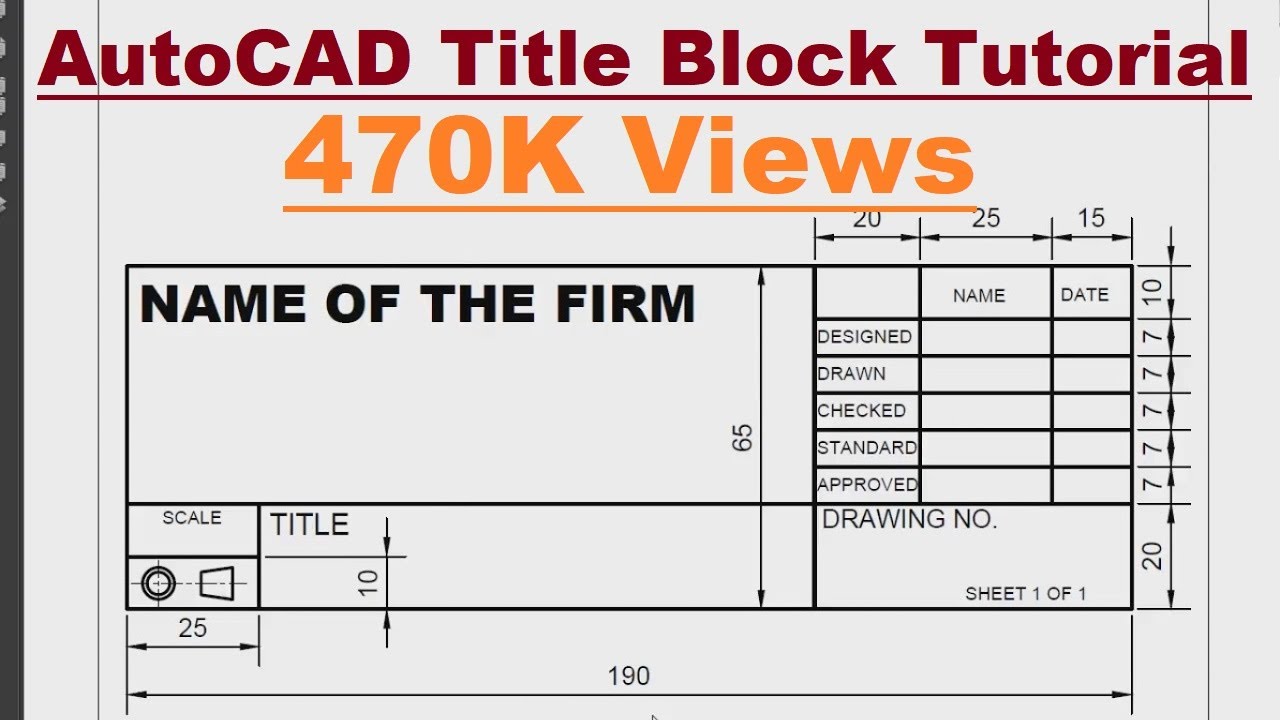

Foils sheets and plates are pretty much the same with the only difference being in thickness. Sheet Metal Drawing Standards 61-80 of 260 results 20 results per page 10 results per page 30 results per page 50 results per page 100 results per page Filters. Above the title block touching the right border line and the title block 4.

The most common sheet metal form is a bend. To the left of the title block touching the bottom border line and the title block. Sheet metal is one of the shapes and forms metal can be bought in.

Enter 1mm in the Thickness field. Increase your capacity by up to 80 with Quintus high pressure metal forming. By admin july 15 2021.

Ad Buy Industry Standards. This includes equipment finishing assembly fastening and the availability of standard dies. Ad We create customized parts in the exact size shape and material you need.

Presses can be classified according to their mechanism. Confirm the drawing formats with your fabricator to be sure they have no difficulty reading or interpreting your design. While the files are presented here in pdf format the source drawings are actually produced as MicroStation dgn files.

The variation becomes larger as the bend angle increases and the part will no longer pass inspection. Lower-left corner of the drawing sheet touching the left and bottom border lines 3. Sheet metal is any metal that has a thickness in between 056 millimetres.

Standard Drawings and Details for Emergency Watershed Protection Projects. However once you expand over all four bends that number increases to a difference of 130 on the overall flat length of the part. Bends can give strength and shape to a part and are formed in a machine using bend brakes.

Guardrail Anchorage Details for Metal Rails and Vertical Concrete Barrier Rail. Bends in the same plane should be designed in the same direction. Select the Bend Extremities tab.

Order and track sheet metal components online through Komaspecs on-demand sheet metal fabrication platform. This specification details the requirements for water based drawing compounds that provide additional lubricity to aid in metal forming operations and must be compatible with current production. 91 For general design work drawing scales shall be full size wherever possible.

It shall be equal to three times of sheet thickness plus bend radius. This code or standard was developed under procedures accredited as meeting the criteria for American National Standards. These factors all play a role in why most manufacturers dont want you to dimension parts in the flat pattern.

I assume they are pretty good. Multiple Format Options Company-Wide Subscriptions. Although notes on each drawing will differ the first note on all sheet metal drawings They are going to consider the fact that.

A description is not available for this item. Customary standard sheet this book book 1 latest changes highlighted 01012018 index of sheets effective standard sheets usc january 01 2017. Our CNC Turret can punch up to 10 gauge with a maximum sheet size of 50 x 120.

93 When increased scales are necessary the scales shall be 21 51 101 201 and 501. The Standard Sheet Books are also available as compiled pdf files for the critical letting dates for which they were. Sheet metal is metal formed by an industrial process into thin.

This video demonstrates how to properly dimension a sheet metal layout technical drawing. Millimetres Mils Gauge. Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula.

Drawing upon the considerable experience of its own CADD Task Force.

Pin On Fabrication Drawing Services

Pin On Solidworks Sheet Metal Design

Pin On Jic Jis Bsp Din Iso Sae Hydraulic Fittings Drawing Size Chart

Pin On Jic Jis Bsp Din Iso Sae Hydraulic Fittings Drawing Size Chart

Solidworks In 2022 Electrical Wiring Colours Solidworks Organic Plants

Pin On Millwork Drafting Casework Shop Drawings

A Simple Custom Counter Counter Detailed Drawings Counter Design